How to Choose a Dust Collection Controller: A Smart Guide for Your Shop

Is your workshop plagued by poor air quality, clogged filters, and machines that don’t get the suction they need? The heart of an efficient dust collection system isn’t just the collector itself—it’s the dust collection controller. This crucial device automates your system, ensuring power and suction are delivered exactly where and when it’s needed.

Choosing the right controller can feel overwhelming, but it’s a decision that pays off in cleaner air, energy savings, and a more productive workflow. This guide will walk you through the key factors to consider, helping you select the perfect controller for your shop’s needs.

What is a Dust Collection Controller and Why Do You Need One?

At its core, a dust collection controller is an automated switch that turns your dust collector on and off in response to tool use. Instead of manually flipping a switch or letting the collector run for hours, the controller activates the system only when a tool is operating.

John Palmer, a professional woodworker and shop owner, explains the impact: “Installing a dedicated dust collection controller was a game-changer. Before, I’d forget to turn the collector on, breathing in dust, or I’d leave it running for an hour by accident. Now, it’s completely automatic. My shop is cleaner, quieter, and my energy bill is noticeably lower.”

The benefits are clear:

- Improved Air Quality & Safety: Reduces harmful airborne particulates.

- Energy Efficiency: Prevents the collector from running idle, saving significant electricity.

- Convenience: Fully automates your workflow—no more forgetting to turn the system on or off.

- Enhanced Performance: Ensures full suction is available the moment you start a tool.

Key Factors to Consider When Choosing a Controller

1. Control Method: How Does It Sense Tool Operation?

This is the most fundamental decision. How will the controller know when to activate the dust collector?

- Current Sensor (Amp Draw Trigger): This is the most common and reliable method. A sensor clamps around the power cord of a single “master” machine (like your table saw). When it detects the amp draw from that machine starting up, it triggers the dust collector.

- Best for: Shops with a primary, frequently used machine.

- Remote Control / Manual Switches: These systems use wireless remotes or strategically placed wall switches to manually turn the collector on and off from anywhere in the shop.

- Best for: Small shops or as a supplement to an automated system for tools not linked to a master.

- Vacuum / Pressure Switches: These sensors detect the change in air pressure or vacuum within the ductwork when a blast gate is opened and a tool starts. This is a more advanced method.

- Best for: Larger, permanently piped systems with multiple blast gates.

- Multi-Method & Smart Systems: Modern controllers often combine methods. They might use a current sensor as the primary trigger but also include a remote for manual override. The latest “smart” controllers can even be monitored and controlled via a smartphone app.

- Best for: Tech-savvy users who want maximum flexibility and control.

2. Electrical Specifications: Powering Your Collector

⚠️ Safety Warning: Always consult a qualified electrician if you are unsure about electrical work. Matching the controller to your collector’s power requirements is non-negotiable.

- Voltage: Ensure the controller is rated for your shop’s voltage (e.g., 120V, 240V).

- Amperage (Current Rating): This is critical. The controller’s relay must be rated to handle the full running amperage (FLA) and, more importantly, the startup surge (LRA – Locked Rotor Amps) of your dust collector’s motor. Always choose a controller with an amperage rating higher than your collector’s requirement.

3. Number of Tools and Zones

Consider your shop’s layout and how many tools you need to control.

- Single-Tool Control: A basic current-sensing controller is perfect for a one-man shop where a table saw is the central hub.

- Multi-Tool Control: If you have several stationary tools, you’ll need a system that can handle multiple triggers. This could be a controller that supports several current sensors or a pressure-sensing system that works with any tool connected to the ductwork.

- Zoning: In large shops, you might have separate dust collection zones. Advanced controllers can manage multiple zones, turning on specific collectors or opening/closing motorized blast gates.

4. Delay-On and Delay-Off Timers

This feature is a mark of a quality controller.

- Delay-On Timer: Briefly delays the collector’s startup (e.g., 1-2 seconds). This allows a large tool motor to get up to full speed before being placed under the load of the collector, reducing strain on both motors.

- Delay-Off Timer: Keeps the collector running for a set time (e.g., 5-30 seconds) after the tool shuts off. This clears dust from the long runs of ducting, preventing clogs and ensuring a clean start next time.

5. Build Quality and Safety Features

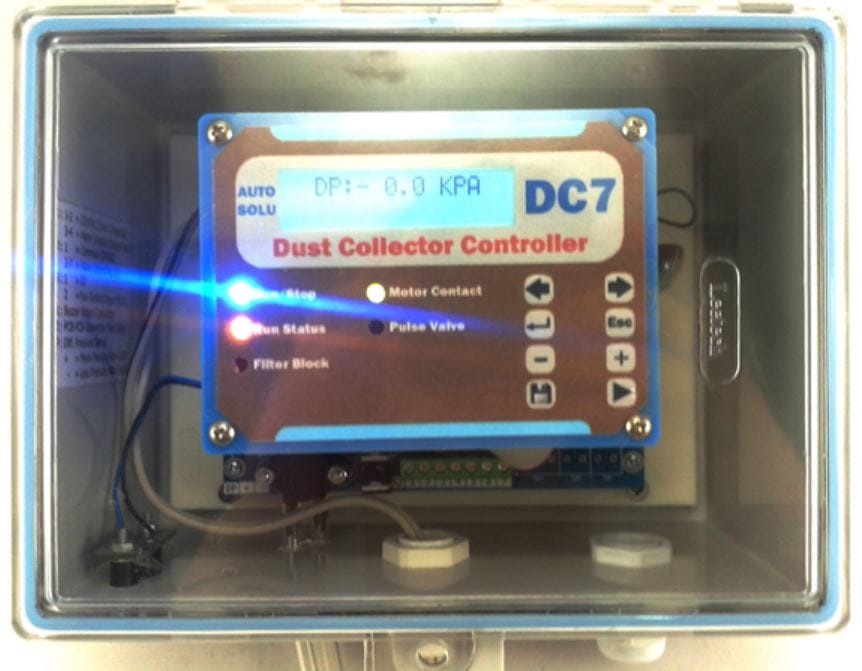

Look for controllers housed in a durable, NEMA-rated enclosure to protect against dust and moisture. Key safety features include:

- Overload Protection: Built-in fuses or circuit breakers.

- Status Indicators: Clear LED lights showing power and activation status.

- Proper Certification: Look for UL Listing or other relevant safety certifications.

Dust Collection Controller Comparison Table

| Feature | Basic Current Sensor | Advanced Multi-Method | Remote Switch System | Smart Controller |

|---|---|---|---|---|

| Primary Control Method | Amp Draw (1 tool) | Amp Draw + Remote | Wireless Remote | App, Voice, Amp Draw |

| Best For Shop Size | Small to Medium | Medium to Large | Small | All Sizes (Tech-focused) |

| Multi-Tool Support | Limited (via Master) | Good | No | Excellent |

| Delay Timers | Sometimes | Almost Always | Rarely | Yes (Configurable) |

| Ease of Installation | Easy | Moderate | Very Easy | Moderate to Complex |

| Relative Cost | $ | $$ | $ | $$$ |

| Key Advantage | Simple, Reliable, Cost-effective | Flexible, Powerful | Ultimate Convenience | Integration, Data, Control |

Making Your Final Decision

“Don’t just buy for your shop today; buy for the shop you’ll have in five years,” advises Sarah Chen, an industrial systems engineer. “Spending a little more on a controller with expandability, like support for a second sensor or motorized gates, can save you from a full replacement down the line. Think about your future tool purchases and shop layout.”

Before you click “buy,” ask yourself these final questions:

- What is the horsepower and amperage of my dust collector? (Check the nameplate).

- What is my primary workflow? Do I mainly use one machine, or do I frequently switch between many?

- What is my budget? Balance initial cost against long-term energy savings and convenience.

- Am I comfortable with the installation? If not, factor in the cost of an electrician.

By carefully evaluating your needs against these key factors, you can invest in a dust collection controller that not only keeps your shop clean and safe but also transforms the efficiency and enjoyment of your craft.